Monthly Archives: March 2019

Building the Xray T4F FWD TC

The rumours had been around for quite some time, but finally towards the end of February this year Xray released their new entry into the FWD class – the T4F.

When it was announced at the same time that an FWD class would be added to the ETS from next season, all the stars finally aligned, and we will hopefully see a bright new future for this great class.

If you are a long-time reader of my simple blog, you will no doubt know I have been promoting this class for close to 10 years already, ever since the release of the Tamiya FF-03 PRO back in 2010. With more car and body releases from major manufacturers on the way soon, if rumours are to be believed, the class is finally building proper momentum!

…

With that intro over, let’s focus on the Xray T4F.

Xray advertise “90% compability” with their current T4’19 TC chassis, which should hopefully help convince more drivers to try the class, as Xray appears to be the most popular TC chassis’ in most markets today. Of course, the fact that it shares so many parts with the T4 is also a way for Xray to help Xray minimise their initial investment into a new class.

Just like the TC cars from Xray during the last few years, the T4F comes with a good specification right out of the box, so it’s a proper racing car.

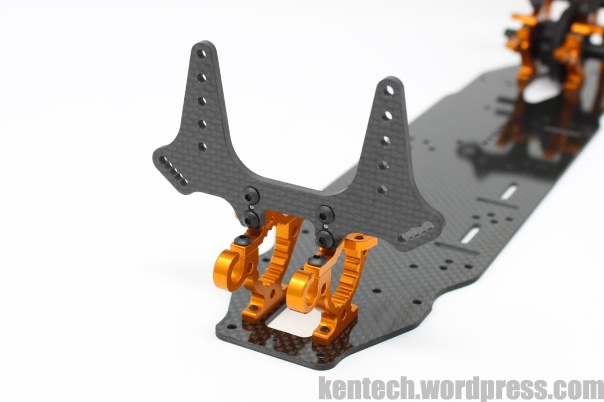

The base of the car is this very narrow carbon fibre chassis plate, unique to the T4F.

Here some info on it:

– 67.5g weight

– 2.2mm thickness

– 76mm width

The front bulkheads are also unique parts for the T4F chassis, as they move the roll-bar bearing holders to behind the diff, to make room for the drivetrain and motor.

The motor mount is a simple piece, mounted to the chassis with two screws, and with one screw to the right bulkhead. This means Xray chose the simplest way to make an FWD, with simply extending the chassis forward to hold the motor mount. This usually results in a chassis that will scrape the ground a lot at the front, but future testing will show how much this affects the car.

One thing I would have wished to see though is that Xray had made more of an effort to place the motor on the centerline of the chassis. Now the motor sits quite a bit to the left, which is not ideal, especially on any car with the motor placed not within the axles. On a rear motor buggy, making sure the motor was right in the centre was an instant improvement, and having tested so many different FWD concepts through the years, I have found it to be equally important on these cars. Of course it is a compromise against room for the spur gear, and damper mounting options, but I’m of the opinion that it is very important to center the motor.

The rear lower bulkheads are exactly the same as on the current T4’19 4WD TC, with roll-bar bearing holders at the rear.

Included with the T4F is the well-known Xray 38T gear differential. By now a very refined product, which was already great when first released many years ago. You will have no problems with this diff.

Xray includes 300K diff oil as a starting point. With a fairly large volume of oil in the diff, this feels rather soft when built. But again, only testing will show reveal what works best with this diff. I would assume you can go harder on the diff oil though based on previous FWD experience.

Take your time when you build diffs with oils this stiff, as it takes time for the oil to settle!

The included layshaft is one-piece aluminium, hollow, and super light.

The right upper bulkhead with the layshaft installed.

The layshaft rolls on 6x10x3mm bearings, and holds a 16T pulley for an internal ratio of 2.375 with the 38T gear diff.

As you can see, the front upper bulkheads have only one postition for the upper arm.

I found it easiest to assemble the drivetrain like this, i.e. first building the right upper bulkhead with bearing, layshaft, pulley. Then attaching this to the car, and sliding the front belt over the pulley. And only then finally adding the left front upper bulkhead.

Drivetrain complete, and Xray obviously chose a belt driven drivetrain for their FWD, which meant they could use the gear diff from their T4. Definitely the simplest solution for a FWD, but is it the best? It will be interesting to see if all cars take this route in the future, or if we will still see 3-gear or 4-gear gearbox FWD’s. The alu bulkhead and belt drivetrain certainly has many positives when it comes to simplicity and lightness.

The belt is 144mm long, or 48T.

Another view of the front end.

Rear upper bulkheads added, obviously the same as on the T4’19, just like the lower bulks, as I already mentioned.

A view of the rear damper tower. This is the part I have read most comments on since the T4F was released, and one can understand that when looking at it. It is obviously very high.

Xray chose to cut a tower like this instead of making new longer body posts. The car uses normal T4 body posts, which you can then mount higher or lower on the tower according to the body shell type you use.

Definitely a super simple solution to this “problem”, and not the most beautiful. But is it better or worse? It is definitely more rigid and stable than long body posts though.

The front damper tower is more conventional for a FWD chassis, with it raised to clear the upper arm and spur gear. The front body mounts also attach to the tower. Both front and rear towers are cut from 3.0mm carbon fibre.

Four damper mounting options at the front, as opposed to the five choices on the rear tower.

The front arms are again T4 arms, but “hard” versions and not the “graphite” arms which you get with the T4’19.

The suspension holders and eccentrics are exactly the same parts as on the T4’19.

At the rear, the T4F gets the same configuration as at the front, with “hard” suspension arms.

The RR suspension holder is again the same as on the T4’19, while the RF 2-piece mounts are without the additional ARS “ears” featured on the T4’19.

All suspension blocks are obviously cross compatible though, and different optional blocks are available from Xray.

The steering is again familiar from the T4 cars. I have always been of the opinion that it is a bit cheap to include plastic steering arms on a pro level chassis, and still am, but when they do, they could at least have included the new alu bearing spacers that they include with the T4’19.

The steering is smooth and works well though. Alu turnbuckles are included.

The upper deck is specific for the T4F, and fully symmetrical. It is made from 2.0mm thick carbon fibre.

With the upper deck fastened with 8 screws, the platform is fairly soft in flex, just as we’re used to from recent Xray TC chassis’. Obviously Xray have a good handle on the flex of the cars, as recent cars have worked very well in almost all conditions.

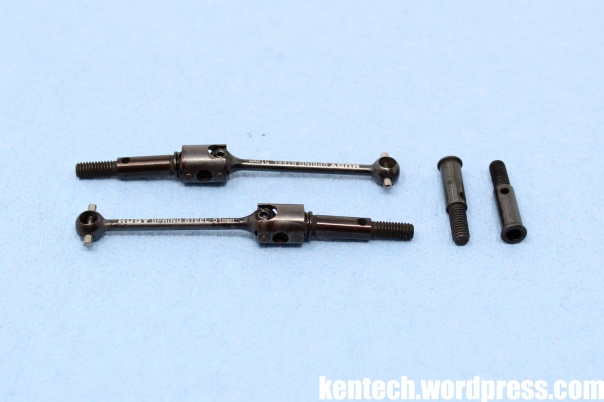

ECS driveshafts are thankfully included, and it’s the 51mm length that you get with the car kit. 50mm and 52mm are optionally available.

The ECS driveshafts do not come assembled, so they need to be built. Hudy graphite grease is included with the kit.

The rear axles are again unique for the T4F, and the spring steel axles are hollow, super light at 2.2g each, and with good precision.

Front suspension completed, with 4 deg C-blocks in “medium” hardness, and “hard” steering blocks. The driveshafts ride on two 5x10x4mm bearings, and a 5mm wide wheel hex is included.

Plastic “blades” go over the end of the driveshafts and into the alu diff outdrives, although fitting the blades was not shown in the manual. A mistake in the first version of the manual perhaps.

The rear upright material is also “hard”, and the hubs hold two 5x10x4mm bearings for the rear wheel axles, which also use 5mm wide hexes just as at the front.

Roll-bars are also included, with 1.3mm bars standard front and rear, and these are precise and and easy to set up thanks to being supported by 4x7x2.5mm bearings.

The front roll-bar shown, which can be easily accessed for fast changes. So far only a 1.4mm optional front bar is available, if you want to test different bars to the standard 1.3mm bar.

The T4F comes standard with the same ultra short ULP dampers as on the T4’19. These are easy to build, and works well. Obviously they are very low when mounted on the car.

Xray 2.6 springs are included for the front, with slightly softer 2.5 springs the choice for the rear dampers in the kit setup. All Xray short springs for these dampers will fit, and multiple options are available.

The front dampers are mounted to the tower with 10.5mm alu standoffs and 16mm screws, which is fairly normal on most FWD touring cars.

As a front bumper, Xray use a standard TC bumper, which is again a reason to make the chassis so long at the front I suppose.

Cut down body posts are used to secure the foam bumper.

The T4F specific foam bumper added, held down with the carbon fibre upper holder cut our of 2.0mm carbon.

Normal body posts are used at the front to mount to the tower.

And a look at the rear body posts mounted in their highest position.

A T4 three-piece floating servo mount is included, which also allows the option of mounting the whole steering assembly to the same plate as the servo.

Xray includes multiple battery holders for many different options.

Obviously simple and cheap to include, but welcome nonetheless.

The initial setting suggested by the manual is this – a cross mounted shorty configuration.

With a shorty battery, this configuration looks like this.

Here’s what the side mounted shorty configuration looks like.

Side mounted full-size 2S lipo.

And finally an inline mounted shorty.

With so many options available, you will be able to choose according to what batteries you already have, and according to the feeling you like. These options are quite easy to try while at the track, and they will have a significant influence on the feel of the car.

Here is the finished Xray T4F then.

The build is super easy, and it is possible to assemble the car quite quickly without making compromises to the finish. This is always a sign of a good quality product.

In some details it feels like Xray have maybe taken one shortcut too many to realise an FWD chassis at the minumum effort and investment. At the same time this is understandable, as they enter a new class which is still only gaining traction.

They have a great base with the T4’19, and it was only logical to design the T4F around that car, and I for one am very happy that Xray actually decided to make a car for this class.

I really look forward to testing the car. Unfortunately, with the carpet season over, and snow and ice still covering the ground up here, I will have to be patient once again.

TRF in 2019 TITC Top 10 Stock & Mod

Seems TRF’s yearly visit to the 2019 TITC was quite successful.

In the extremely high-level Modified class Takuma Sasaki made the A-final, qualifying 9th and finishing 10th overall with his TRF419XR in a field of factory pro drivers.

In the Open Brushless 13.5 class Tamiya’s own Takayuki Kono made qualified and finished 5th overall with his TRF419XR.

Not bad for for a manufacturer who many still seem to (wrongly) think pulled out of making TRF competition cars…

Takuma Sasaki

Open brushless 13.5 top 10

Takuma Sasaki’s TRF419XR

Takayuki Kono

TRF designer Kiyo Suzuki

Protoform Europa FWD Body

I finally got my hands on a Protoform Europa body, so let’s take a closer look!

The Europa is the first ‘made for FWD’ body from one of the major body shell manufacturers, but it certainly won’t be the last, with more releases coming soon from Protoform’s competitors, if rumours are to be believed

Some might say well what about the Mon-Tech Rally bodies, but those were never originally made for FWD cars, and while they have been OK with the lack of alternatives so far, I certainly hope some future rules will be restrictive enough to demand bodies that closely mimic real FWD racing cars.

The Protoform Europa is obviously modelled after the Seat Leon Cupra TCR, later called just Cupra TCR, which was actually the first homologated TCR car. Protoform’s version is not called a Seat or Cupra because that would require licensing, but still features fairly realistic lights and other stickers, and I think Protoform set a good example in this regard with the Europa body.

I will say though that even better realism would (always) be my wish, but it is still good enough for a first try. There are some lines at the front and around the headlights which make it look a bit wrong when you take a closer look (you can compare with the last photo in this post of a real Leon TCR).

The body is also too wide ahead of the rear wheels (205mm!). It is otherwise 195mm as it should, so that particular issue appears to be something that happens as a consequence of cutting out the body. Perhaps something that can be sorted by some small change to the body mold. Also the rear wing is mounted too far forward originally, but as you can see I made an extension to place it about where it should be. The wing itself is about the right size though, which is very important for a realistic look.

Apart from those few small future possibilities for improvement ( 😉 ) I think overall it’s still a decent looking body, and very very welcome for the FWD class. I certainly hope we will see more TCR bodies available soon for this class.

Some details:

Weight: 97g (as seen with heavy paint and extended wing mount

Width: 195mm (except rear fender extension mentioned in text)

Length: 425mm (excluding wing)

Height: 130mm (body only (0mm ride height) – lower line cut according to markings)

As you can see, the Europa is much lighter than most FWD bodies I compared last summer, and will have a significant advantage from that. The class definitely needs a minimum body weight. What that limit should be I cannot say, but certainly the Europa is at the limit of what lightness should be allowed, if not already too light, as a heavier weight limit should allow better realism.

I very much look forward to testing the Europa, but that will unfortunately have to wait until it is possible to run outdoors again up here. I will most probably report back then! 🙂

In this picture (below) you can see how wide the front of the rear fenders are.

Here you can see the rear wing mount extension I made using a piece of 0.75mm Lexan and some carbon fibre reinforcement.

Real Seat Leon TCR car for comparison.