Search Results for trf421

TRF421 Interviews @ Shizuoka 2024

As I mentioned in posts yesterday, this week the 62nd Shizuoka Hobby Show is held in Japan, and Tamiya is displaying the new TRF421 Chassis Kit for the first time on their domestic market.

This brings some good content on the car, even if it’s in Japanese, and today I came across these two interviews about the TRF421 with designer Takauki Kono.

These interviews give a lot of background information on the development and reasons for making the TRF421 the way it is, as well as information on what we can expect in the future.

__________________________________________________________________________________

The first one from RD2 magazine, and I post a translation of the original interview here.

The Rajitsu editorial team asked the manufacturer!

Extra Edition ‘Tamiya TRF421

The TRF421, which finally appeared with a brand new platform after a 2 year interval from the TRF420X, seems to have been renewed not only in the suspension shape but also in all other areas. What is the background to the full model change?

First, Tamiya’s high-end models are symbolic, so it is our premise that we will continue to produce them without interruption. However, if the model cycle were to be renewed every year, as is the case with other companies, we wondered whether users would be willing to buy a kit priced at 100,000 yen every year due to various cost increases. This was the question we had to answer. Furthermore, once a platform has been created, we and our users will get closer to a situation where they ‘understand the machine’ by running it a lot, but it takes time, not months but years, to get close to that situation, especially if major changes are made. I think it takes time, especially when major changes are made. The 420X is an evolution model of the 420, so I feel that 420 users can also enjoy a new riding feeling with the new parts. The 420 platform has been enjoyed by so many users that it’s time for the manufacturer to make a new offer. So we decided on a brand new configuration.

I see. Once a platform has been created, there is room for it to evolve based on understanding, which is why the model cycle is longer, isn’t it? It’s a great policy, because it’s a very welcome situation for users to be able to enjoy what they’ve got for a long time!

Unlike previous suspension systems, the TRF421 uses a global-standard upper and lower A-arm type suspension system with a pipod, and incorporates a number of similar configurations and mechanisms to other companies, such as one-touch exchange spur gears, but what was the development concept behind the TRF421? What was the concept behind the development?

In reviewing the platform from scratch this time, we of course checked the prototype touring cars running in competitions around the world and the models that have gone on to become commercial products. I am aware that there have been many trials and tribulations, including many bizarre ideas and structures in pursuit of performance. In the midst of all this, I combined each element to find what I thought was the best shape, while comparing it with the shortcomings I felt during the development of the previous model. The result is the TRF421.

We will continue to incorporate the good points of other companies’ models as long as they will result in a good product. I am aware that immediately after the launch of this car, there was talk that it was similar to other companies‘ cars, but I am confident that I have designed this car with the optimum configuration for the driving image I want to achieve, so I hope that you will take it in your hands and feel whether this car is a copy of other companies’ touring cars or not.

I see. Even if it looks similar, how will it function as a car? So you always had this in mind when designing the car. In that sense, it is true that the front, rear, upper and lower A-arms are made of resin material, not the usual carbon material, and the upper A-arms seem to have been designed to be quite slender when you look at the real thing. Can you tell us why this configuration was chosen?

Firstly, we identified the points where we were dissatisfied with the I-arm suspension on the 420X: with the I-arm type, the upper arm is inevitably a single arm, which is not as rigid as the lower arm. Furthermore, the lack of rigidity made it impossible to extend the suspension length any further. Therefore, during development, we of course tested an upper arm with multiple turnbuckle arms, but this not only made adjustment more difficult, but also did not work to our advantage in terms of weight. So the first point was to secure the missing rigidity by changing from the situation where it was originally possible to run with just one I-arm to an A-type upper arm. However, it was still possible to drive with I-arms and we wanted a bit more rigidity, so we pursued the thinness and lightness of the upper arm just enough to secure the required rigidity. That’s why it looks so thin.

Next, for the lower arm, we are aware that other touring cars use carbon material, but in our testing we found that we could achieve the same performance with resin, so we used resin, and to be honest, we consider this lower arm to be a consumable item. We also chose to use resin to keep the price of aftermarket parts down.

The suspension works by the combination of upper and lower arms, so it is good if the desired strength and rigidity can be secured during the operation. We also wanted to increase the length of the suspension a little more, which we were able to achieve with this configuration. The drivetrain parts have also been renewed accordingly.

I see. The points you wanted to improve on the previous model were clear, so the layout was found to improve those points, and the shape and materials of each part were also considered for continued use. Incidentally, in the drivetrain area, it is common to see kits from other manufacturers with diff covers fitted, but this model does not have a diff cover?

Yes, it does. It is bare. This is because if there is a cover, there is no place for foreign objects to escape when they come close to the diff, and with this structure, rigidity and strength can be secured without having to connect the left and right blocks with covers. After all, it is advantageous for a touring car to be as light as possible.

Even a small amount of weight can become a big thing if it is piled up. It is also very interesting to hear about the escape routes for foreign substances. If they get in, they can lead to damage, as they are not sealed.

Next, the 420X came with two types of chassis, but this time only a carbon chassis is included.

We know that there were a lot of opinions about including two types of chassis in the previous model, and we thought it would be a good idea to include two types if possible, but in terms of keeping the kit price down, only one chassis is still a realistic answer.

So, should aluminium or carbon be the standard? As a developer, my interpretation is that there are at most 10 to 20 situations where an aluminium chassis is required, out of a total of 100 driving opportunities. In many situations, we decided to use a carbon chassis because we believe it will allow us to exploit the potential of this model.

However, we decided to include two types of upper decks in the package, as this would reduce the number of options available. The running characteristics of the one-piece and separate types are very different, so by using them differently, we assume that about half of the situations we mentioned earlier, where you want an aluminium chassis for 10 or 20 runs, can be handled by selecting the upper deck.

Thank you very much for your very interesting talk. Incidentally, since you mentioned the upper deck, I would like to ask you about the driving characteristics of the TRF420. Is this the same concept for the TRF421?

Yes, the TRF421 is designed based on exactly the same concept. The chassis is one of the elements that create flex. However, if you just let go, you won’t be able to move forward, so the question is how much flex? The idea of the upper deck is to adjust the amount of flex. Basically, the TRF421 was developed based on the concept of ‘easy, straight running’. You could say that all the elements have been prepared for this purpose. Therefore, as designers, we have developed the TRF421 with the assumption that it would be a one-piece type with a bridge on top of the chassis, but we have prepared a separate type because it is true that some users want the TRF421 to move more quickly. We hope that by first driving with the one-piece type, you will get a better understanding of the basic characteristics of this vehicle.

The concept of ‘easy, straight driving’ gives the impression of being very easy to manoeuvre, but it is also true that there are people who want the car to turn more. It is also true that there are people who want the car to turn more, so being able to adjust the upper deck is a very good trial!

I’ve heard so far, but this is the kind of car I want to make! I understand that each element has been combined to achieve this, but I honestly feel that there are no points that are unique to the TRF421! Please tell us if there are any points that you think are clearly different from other companies.

This also depends on how you think about it, but I also think that bizarre structures and ideas are a wonderful trial, but I think they are risky as a means of ensuring the realisation of an ideal.

I think it’s because Tamiya is a manufacturer, but also because people of various levels of performance stability want to drive a high-end model! My view is that the components should be basically conservative.

The TRF421 features a stabiliser. The installation method is also unique, and I asked the factory to manufacture a stabiliser that would give the performance I wanted with the installation method I used this time. The factory that manufactures the stabilisers told us, ‘That’s impossible! but we managed to make it happen. To be honest, this is a stabiliser made of a material that is unique in my opinion, and is a major component of the TRF421’s performance, so I hope that you will first assemble it according to the values in the manual to get a feel for how it feels.

It’s equipped with such an amazing stabiliser! That alone makes me want to try running it. Incidentally, you mentioned ‘following the instructions’, but is it important to first follow the values in the instructions for the kit you have developed, and not just for this?

This is also from the point of view of the designers and developers, but this model is a particularly high-end model, so we have made no compromises at all with the setting values for each individual part and each section. We have done a lot of test runs and tried many prototype parts. As a result, we have chosen the parts that make this machine run best, and we have developed the settings for each part. Of course, we don’t say that changes are not necessary because the user has his or her own preferences, but we would like you to build the machine as described in the manual and run it to get a feel for the standards. If you can then give us your feedback, it would be valuable information for the next model.

I see. Knowing the standards is important no matter what you are working on, isn’t it?

In that case, it seems to me that the new model will also be a long-life-cycle model, what do you think?

As I said at the beginning, we have just created a brand new model, so first of all, I want to spend a lot of time getting to know this machine and its users. Then we will develop the Evolution model, so that people can enjoy this model even more.

So, I think that the basic parts of one model will continue in the same form for three to four years, approximately. We are assuming at the moment that the basic parts of one model will remain the same for three to four years. Of course, if circumstances change, it may be earlier or later.

As a business, there will be various circumstances, but if it is a model with a long life cycle, it will be easier for users to think about picking one up. It makes it easier for them to think about it.

We’ve heard a lot about the TRF421 so far, but can you tell us at the end what kind of user you have in mind for the TRF421?

Tamiya is not a works-based racing manufacturer, but as a designer, we honestly want to pursue the most advanced performance, and we are proud that the TRF421 is a model that is not inferior to any of our competitors.

That is why we have developed this model to be available not only to Tamiya model enthusiasts all over the world, but also to all users of competitive touring cars. This is also true for the shape of the rear body post,

It has been newly designed in a way that allows both the use of Tamiya bodies and the use of competition bodies.

This is a model that we are confidently sending out to all touring car users.

Thank you for telling us that you are really confident about this TRF421.

We look forward to the next model!

The TRF421 is now in the phase of being delivered to you, so we are developing the next machine one after another. Please look forward to it.

Thank you very much for talking to us so far and we look forward to the launch of the TRF421!

Thank you very much!

The second interview/presentation about the TRF421 is in video format, by the excellent SudapyonRC youtube channel.

Use translated automated subtitles to understand what they are talking about.

Finally, a few more detail photos of TRF421 diff and spool, front and rear drive shafts, as well as the new Ultra Short Big Bore TRF USBB dampers.

Souta Goto TRF421 from TITC 2024.

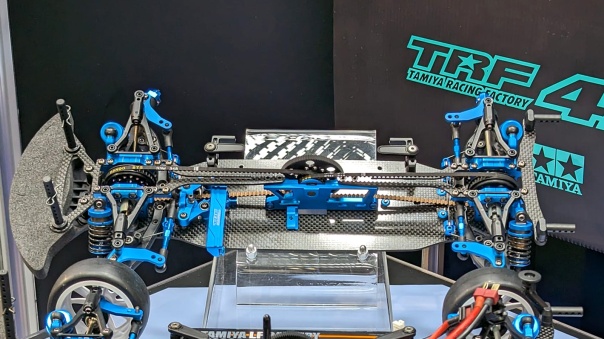

TRF421 @ Shizuoka Hobby Show 2024

The 62nd Shizuoka Hobby Show is open from today, and Tamiya displays the TRF421 publicly in Japan for the first time.

Above you see Souta Goto’s modified class 7th place car from TITC 2024.

Here the production TRF421 chassis kit. Note rear body post extensions for vertical rear body mount.

Photo #3 is of a partly assembled TRF421 with info on various parts and changes from the previous car.

* Post updated with further photos from Shizuoka here below *

More details of Souta Goto’s TRF421 from TITC.

Photo showing the bottom of the chassis. Note just one regular motor mount screw.

Below a first look into the new TRF USBB dampers, showing the new upper seals which now sits recessed in the damper body.

Tamiya TRF421 Parts List

The release of the TRF421 Chassis Kit from Tamiya is getting closer, and more information is beginning to come out.

To get a better idea of the parts and part numbers for the 42384 TRF421 Chassis Kit, I made this parts list out of the information available.

By reading it closely you’ll get a bit more information on the smaller details of the TRF421.

* Update – noticed some errors in the supplied material so I now updated the list:

Here a screenshot from last weekends Tamiya Live, where you see the TRF421 with rear body post extension set to fit Tamiya bodies. From the parts list it appears that the extension set is included in the kit.

Tamiya TRF421 Official Product Info

Tamiya have published the product details of the production TRF421 chassis kit, with official photos and description.

Here follows the full detailed description of the new TRF421 (alternative texts in cursive are translated from Japanese presentation as it contains more info).

42384 TRF421 CHASSIS KIT

This R/C model assembly kit creates the 2 belt-driven 4WD TRF421, the latest model in the line of TRF chassis; its newly designed carbon fiber upper and lower decks move the motor 22.7mm further forward than on the TRF420X, while the center shaft is in the chassis center and drive belts are of equal size; pulleys are also a new design. The upshot of this is greater pitching stability on the throttle. Bulkheads have a new design for a lower center of gravity, and new USBB (ultra-short big bore) dampers are mounted via aluminum stays: they can be fine-tuned with spacers. The suspension uses upper and lower A-arms for superior rigidity, with identical lower arms front and rear that have a longer span for more linear roll that translates into more control.

The 2-belt drive 4WD touring chassis bearing the name “TRF”, the pinnacle of Tamiya R/C, has been fully remodelled for the first time in 2 years. The newly shaped carbon lower and upper deck moves the motor position forward 22.7mm compared to the previous TRF420X. The centre shaft is positioned in the centre of the chassis and the drive belts are of equal length front and rear. The front and rear pulleys also have a new shape. This change reduces pitching during throttle operation for a more stable drive. The front and rear bulkheads have also been reshaped for a lower centre of gravity, and new USBB (Ultra Short Big Bore) dampers are mounted with aluminium stays. Fine angle adjustment is now possible using spacers. The suspension uses highly rigid A-arms top and bottom. The lower arms are the same front and rear, with a longer span for a more linear roll posture when cornering and improved stability when controlling the car. With an optimised drivetrain, chassis flex and low centre of gravity, the TRF421 chassis is set to reach new heights of performance.

The center shaft is moved into the middle of the chassis, and belts are of equal size, while pulleys are new: the result is less pitching on the throttle, and greater stability.

The centre shaft is positioned in the centre of the chassis and the drive belts are of equal length front and rear. The front and rear pulleys also have a new shape. This change reduces pitching during throttle operation for a more stable drive.

Front and rear bulkheads contribute to a lower center of gravity. Ultra-short big bore dampers are mounted via aluminum stays.

The front and rear bulkheads have also been reshaped for a lower centre of gravity, and new USBB (Ultra Short Big Bore) dampers are mounted with aluminium stays.

Front and rear bulkheads contribute to a lower center of gravity. Ultra-short big bore dampers are mounted via aluminum stays.

All new damper: the USBB damper is 5.5 mm shorter than the SSBB damper, resulting in a lower centre of gravity and reduced weight. This dramatically improves dynamic performance. Two types of shock ends are available, one for the front and one for the rear, with a 0.5 mm difference between the front and rear to allow the piston height to be adjusted to the same level according to vehicle height.

With the motor 22.7mm further forward than on the TRF420X, the center shaft is now in the chassis middle. The spur gear is affixed using a single nut for easier pit-work.

The centre shaft is positioned in the centre of the chassis by moving the motor position forward by 22.7 mm compared to TRF420X. Equal-length belts front and rear reduce pitching moments during throttle operation, resulting in stable drivability. The spur gear can be fixed with a single dedicated nut, greatly improving workability when removing and installing the spur gear.

Stabilizers have had an overhaul, and now feature a common design front and rear, and are positioned lower than the drive shafts. The kit includes one each of 1.0mm and 1.2mm rods, and two 1.1mm parts.

High-precision stabilisers with a common design for front and rear, based on a review of the materials and hardened parts. The mounting position is lower than the driveshaft for a lower centre of gravity and easier maintenance. The kit includes 1 x 1.0 mm, 2 x 1.1 mm and 1 x 1.2 mm sets, allowing for setting changes.

The revamped suspension employs A-arms; lower arms are ball-attached. The lower pivot is positioned on the inside of the bulkhead to keep chassis width the same while allowing the long span lower arms. Lower arms have neutral toe on the inside, and toe angle is applied on the upright side.

Suspension is a highly rigid A-arm with each part newly designed. The lower arm has a longer span and the mounting has been changed from a block type to a ball type. By placing the lower pivots inside the bulkhead, a 7 mm longer span was achieved without changing the overall width of the body. Lower arm toe angle set to 0° on the inside and toe angle adjusted on the upright side.

1-piece and 2-piece upper decks are included; use them to adjust flex. Using more or less screws to affix it to the motor mount lets you further fine-tune your setup.

Upper deck available in one-piece and two-piece versions for chassis flex settings. Multiple dedicated mounting screw holes for fixing to the motor mount allow a variety of chassis rigidity adjustments through a combination of screw mounting.

Tamiya TRF421 in RC Magazine

TRF421 article in latest RC Magazine.

Translated text:

Tamiya’s flagship touring is undergoing a full model change for the first time in four years.

Not only the chassis and upper deck, but also the suspension and drive system have been renewed, and a completely new concept machine has debuted.

Check out this high-performance machine that can be trained to transform from stability-oriented to combat-like driving!

We hope that drivers of all skill levels can experience the TRF experience, and we have also provided plenty of know-how gained from the latest racing scenes.

“TRF” is the title given to Tamiya’s high-performance models. The team has a long history, starting in 19xx when it was established as an official racing team, and its activities are not limited to Japan, but also feedback the technology gained through … to races held around the world. This is the driving force behind creating outstanding RC cars.

The latest in the series, the TRF421, has a low center of gravity chassis with a new arm support.

A new type of ultra-short big bore damper was also used for the oil damper, and the station was equipped with front and rear equal length belts. In addition, two types of upper decks, one-piece and separate, are included with the kit, allowing for a wide range of settings. It is now possible to optimize to a high level according to the driver’s preferences and circuit conditions, achieving amazing optimization beyond imagination.

TRF421 & TRF History on Tamiya Live

Tamiya broadcasted two RC Live sessions yesterday (Sunday March 24).

The first session had a segment dedicated to the TITC, but unfortunately there was no detailed look at the TRF421’s used at that race, only a look at the TT-02 used by Kiyo in the special Porsche class.

The second Tamiya RC Live session was more interesting, with Satoshi Maezumi and Takayuki Kono first going through the history of Tamiya Racing Factory, and many of the TRF touring cars sold over the years. Even though Tamiya RC Live is Japanese only, the TRF history lesson is worth watching with translated automated subtitles as there is a fair bit of interesting background information mentioned by Satoshi.

After this there was again a special in-depth focus on the TRF421, with some new information told. A couple of things that stood out for me (if I did understand correctly from the translations):

- The TRF421 was developed over 4 years, all the way since the TRF420 was released

- There were two directions during development, with one more conventional (like the TRF420/420X derived prototypes we have seen), but the TRF421 direction was always the main plan

- They may still be attending the Worlds this year with Souta Goto, but nothing confirmed, negotiations within Tamiya still under way

- An aluminium chassis option is in development

- A TA09 is still well in the future with the TA08R just released, but you get the impression that it could look a bit like the TRF421…

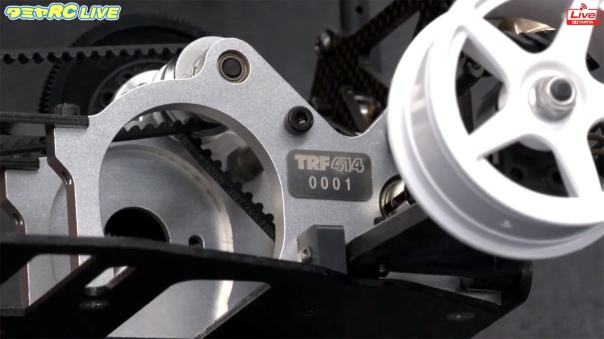

Ultimate TRF414? 😉

Tamiya TRF421 Debut @ TITC ’24

When the all new TRF421 chassis was presented by Tamiya around one month ago, it was stated that the first race with the car would be the world famous TITC.

Tamiya have always attended this race and it is closely linked to it since the TITC – Thailand International Touring Car Championship, is organised by the official Tamiya Thailand distributor Siam Tamiya Co. Ltd.

As Tamiya does not have an official race team, and the TRF421 is not yet released, only three cars were present at the race. These were run by TRF designers Kiyo Suzuki and Takayuki Kono in the open stock class and Souta Goto in the modified class, all three of them Tamiya Japan employees representing their employer at the race.

As the race got properly started it was soon obvious that all three drivers had good pace in the difficult conditions, especially when you consider the level of competition and the three drivers lack of international racing experience over the last couple of years.

The biggest surprise, and the most impressive performance was that of Souta Goto in the modified class, as he fairly securely qualified for the A-final in 8th place.

He did this with a 5th and 8th place in the second and forth qualifying rounds, for an overall quali score of 298. But the fact is that had he gone just 1 second faster in the fourth round, he would have got second in that round, and 303 pts, which would have been enough to qualify fouth overall!

That is of course just speculation, and any race is full of these “what if’s”, but I just think it’s a good way to show how much on the pace he was with the new car in its first ever race.

In the end he qualified 8th, and finished 7th overall – a hugely impressive and encouraging result for a brand new car and no factory team…

Of course, the result is not an absolute surprise, as the TRF421 always looked like it could be quite a good design, and anytime you combine a good driver with the backup of TRF and perhaps especially Kiyo Suzuki, the results have generally been quite good.

Don’t forget that he was a strong part behind the years of success with the TRF team and Marc Rheinard.

Even with that, when you look at the other drivers in the A, and even all the way through the B-final, this was throughly a high-level race and a superb result.

This was really dream debut for Tamiya with the TRF421, and it was obvious to see the excitement when people started to notice what was about to happen.

Even after all these years, there is still a certian myth around Tamiya and TRF, and overall a lot of people seem very happy to see them just show up and produce a surprise result with a brand new car at the highest level of racing.

I think this overwhelming positive reaction might well have come as somewhat of a surprise for Tamiya themselves.

Over the past couple of days I already heard various shop owners express that while there was already a good interest in the car from customers, there is now an obvious rise in questions, and many expect there will be a fair few more TRF cars at the tracks soon compared to the prvious couple of years.

Tamiya did not only make the modified A final, as Takayuki placed his TRF421 in the top ten of the highly competitive open brushless (stock) class.

Taka qualified in 10th place, and was 8th overall after the three finals.

Kiyo also raced in the open stock class and I thought he did very well as an older driver to qualify for the C final in 28th place, in a competitive field of over 120 drivers.

He also competed in the special Porsche (TT-02) class at the TITC, where he qualified third and finished second after the finals.

I wanted to mention this class as well because of the extremely beautful Porsche 992 GT3 body he run in this class. This is what RC (also) needs!

Finally a look at Souta Goto’s TRF421 chassis, thanks to the chassis focus featured by Red RC in their event coverage.

Things I have noticed so far:

– The most obvious thing is the unanodised motor mount. This was not on the cars during practice early in the week, as pictures from then show a normal blue anodised motor mount on all cars. This means that there has been some kind of change to it, and that these prototype parts were probably prepared shortly before the race. I must admit I have so far not noticed what’s different other than the finish of it. If any of you have noticed or know, then let me know and I will update.

– super short springs front and rear

– Souta Goto’s car feature the split upper deck, while the other cars used the one-piece upper deck, at least earlier in the week

– white driveshaft blades at the rear and black front blades

– all screws used to mount the motor mount to the chassis

– rear flex plate used

– no front bulkhead stiffener installed

Images used in this article are thanks to Souta Goto, Red RC, TITC and 陳瑞皓.

Another Tamiya TRF421 Description

Following the extensive official product description published early last week, here’s another version of it, coming from Tamiya USA.

42384 TAMIYA 1/10 R/C TRF421 Chassis Kit

Tamiya’s TRF R/C designers never rest. They are constantly looking to bring our most hardcore R/C racing fans the absolute best features able to be squeezed into a 1/10 scale touring car chassis! After two and a half years of development, we now bring you the ALL-NEW TRF 421. The highest end touring car chassis series we produce has received a whole new suspension and layout makeover!

New features:

This 2-belt driven 4WD carbon fiber double-deck design is loaded with new features such as an updated drivetrain, a new lower deck shape, front and rear upper A arms, and new shorter dampers, all of which promise to translate into serious speed on the track! Other notable features include a choice between one- and two-piece upper deck layouts for different chassis flex characteristics, plus updated suspension geometry that keeps the chassis more stable.

Key Features:

The Drivetrain uses a front direct coupling and rear oil-filled gear diff. Equal length front and rear drive belts minimize pitch.

Suspension Arms are a rigid “A” design with 7mm longer span compared to the TRF420X for stable roll, while upper arm mounts can be slid to adjust camber.

Three damper pivot positions are provided.

Dampers are 5.5mm shorter than on the TRF420X, for a lighter chassis and lower center of gravity. Attach them directly to aluminum mounts and fine-tune with spacers.

• 1/10 scale R/C chassis assembly kit.

• The drivetrain features the motor position moved 22.7mm toward the chassis center compared to the TRF420X Chassis Kit and has identical length front and rear drive belts for stable drivability.

• With updated setup of spur gear and drive belts, only one dedicated nut is required to attach spur gear, which enhances efficiency of maintenance.

• The new lower deck is smaller compared to the one used on the TRF420X Chassis Kit to limit ground clearance when the chassis experiences roll.

• Choose from two types (one-piece and two-piece) of upper deck. Changing screw positions allows five setup patterns in total.

• A-shaped suspension arms are employed for higher rigidity. (The 420X chassis kit uses I-shaped suspension arms.) Longer lower arm spans limit swing width and ensure stability when the chassis experiences roll.

• Along with longer lower arm spans, front and rear suspension setups are changed from suspension blocks to suspension balls. Roughly 7mm-longer arm spans limit swing width and ensure stability when the chassis experiences roll.

• Toe angle can be adjusted by uprights. (The toe angle of lower arm inside is 0 degrees.)

• Three attachment damper positions (inner, middle, and outer) on front and rear lower arms are offered by two types of aluminum bushings.

• Changing positions of upper arm mounts by screws allows changes to front and rear caster angles, which is suitable for current high-downforce races. Front caster available angles: 3, 4, and 5 degrees. Rear caster available angles: -.5, -1.5, and -2.5 degrees.

• Dampers are shorter by 5.5mm compared to the 420X chassis kit, which provides an exceptionally low center of gravity and reduces the weight, for a more dynamic driving experience.

• Dedicated damper ends are used front and rear to ensure the same piston level.

• New damper oil seals (Item 51738) are used to keep the maximum oil amount and to make use of oil dampers efficiently.

• While the 420X chassis kit uses carbon fiber damper stays, this chassis kit employs aluminum mounts for precise angle adjustments based on the number of spacers used.

• Front and rear differential pullies are newly molded while direct coupling and oil-filled gear differential are employed at front and rear, respectively. (The currently sold Hop-Up Option and Spare Parts can be used.)

• The front features double cardan joint shafts while rear employs lightweight universal drive shafts. New axle shafts (Item 42388) and 45mm drive shafts (Item 42387) are also used for both front and rear to ensure efficient drivetrain and maintenance.

• Newly designed lightweight rear wheel axles enhance durability.

• Precision stabilizers are attached at a lower position than drive shafts for efficient maintenance of drivetrain. Includes 1.0mm diameter (x1), 1.1mm diameter (x2) and 1.2mm diameter (x1).

• The steering system pairs dual steering arms and Ackerman bush with a new steering bridge. Three types of new spacers featuring different diameters allow steering angle adjustment.

• Includes Sealed Ball Bearings from the TRF series for efficient rotation and Item 22078 Aluminum Differential Holders (0.8mm Offset, 2pcs.).

• The newly molded quick-plate design battery holder does not require tape for attachment. Depending on the battery pack equipped, change positions of spacers and posts. Shorty pack compatible.

• Comes with a carrying case dedicated to the TRF421 chassis kit.

• Required to complete: 2-channel radio, low-profile steering servo, ESC, 540 motor, wheels and tires, 190mm TC or Sports Car body, 7.4volt battery pack and compatible charger.